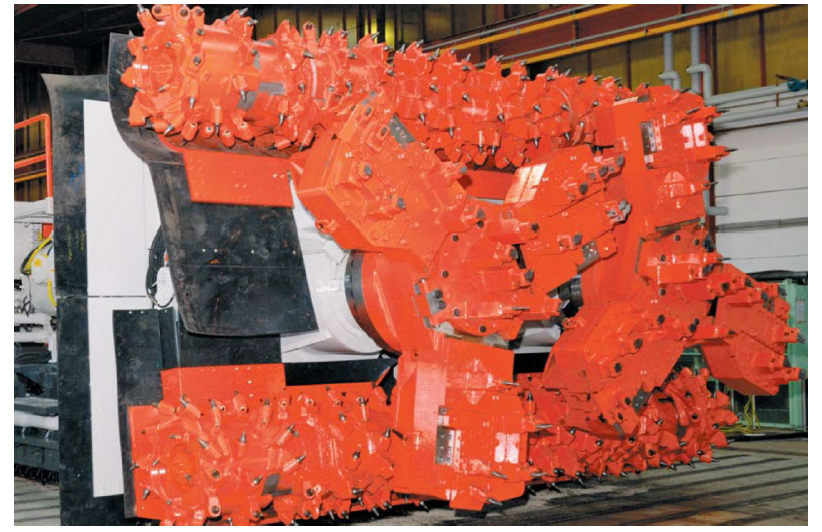

Our rock mine tools are well known to all major mining clients around the world.Our close attention and continuous development work ensure the latest technical solutions for the most demanding rock conditions and the most powerful rock tools, all for the benefit of our customers.

Our products undergo extensive laboratory research and are then thoroughly tested in the field.Final evaluation and refinement to provide the highest grade of product that represents the rock mine name.Our spirit of innovation and high levels of engagement run through every product.Quality oriented global development is good.

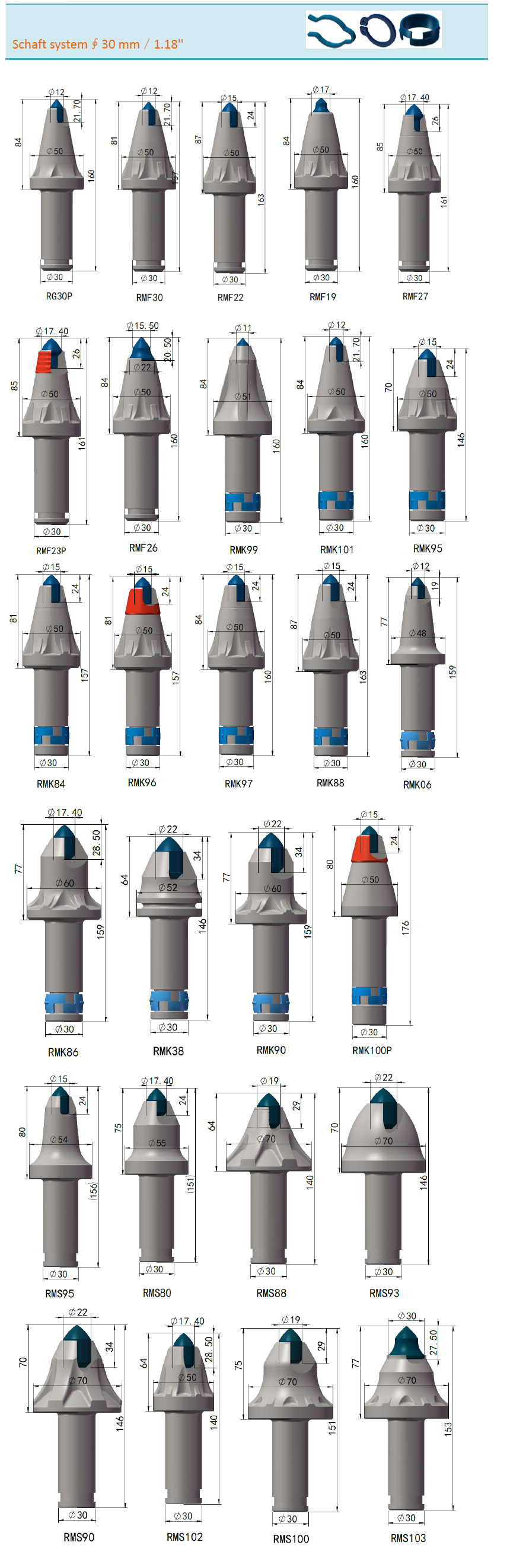

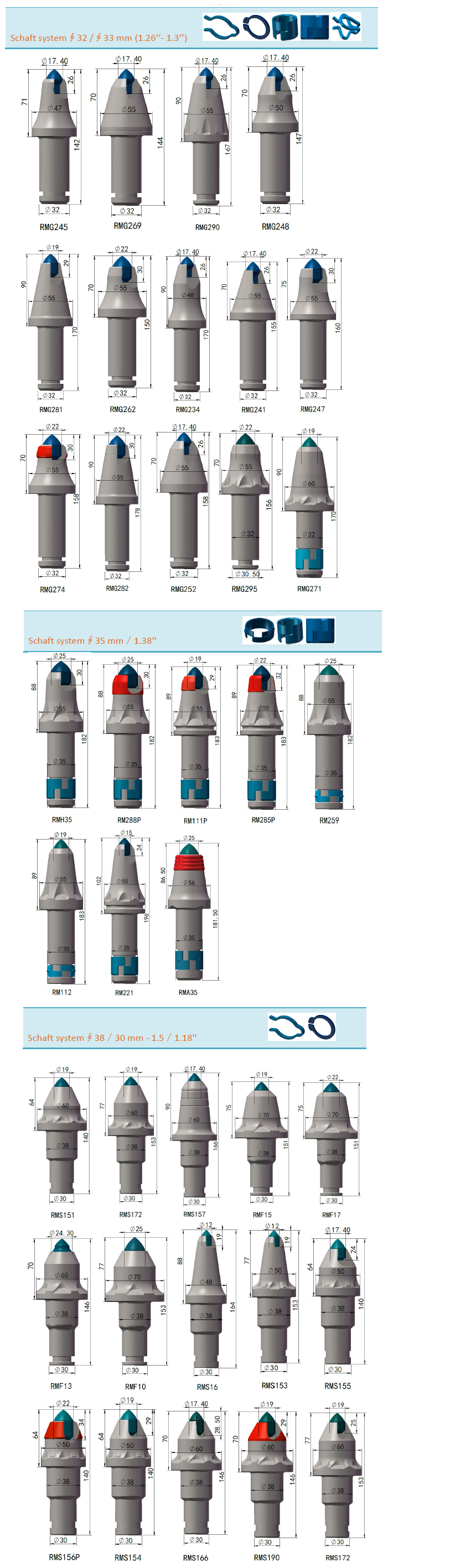

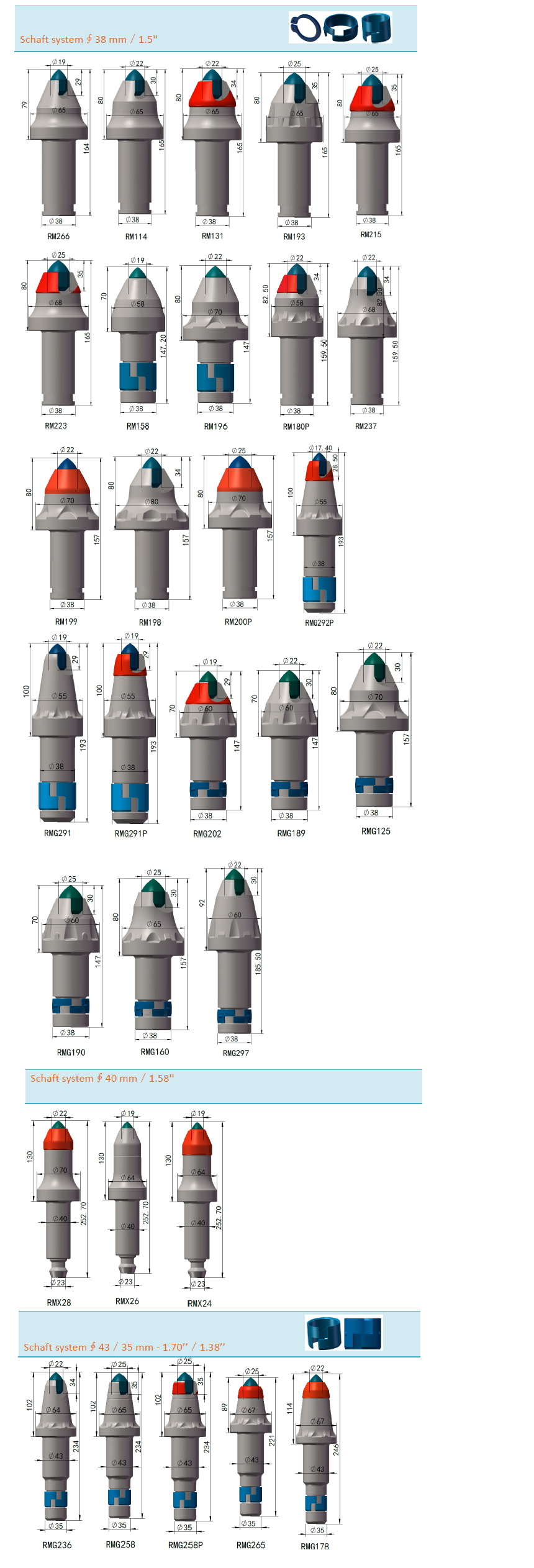

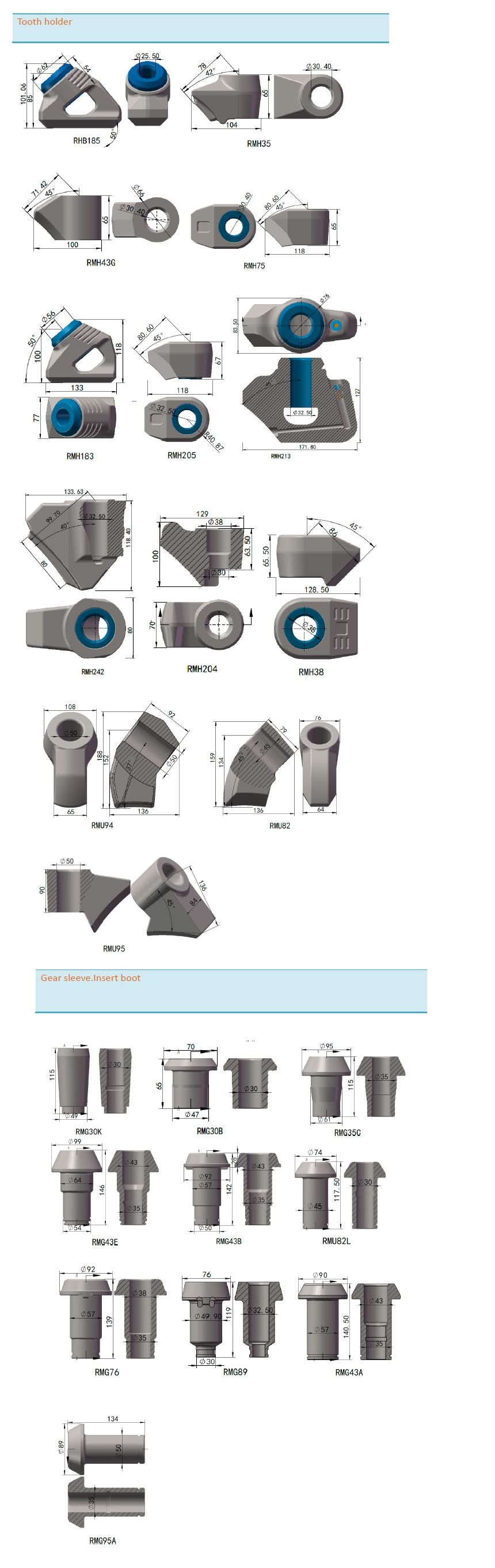

Type:

Cutting teeth for sandvik equipment:

Q8KX-30, Q8KF-30, Q7AU-38, P9QA-25, P9MS-25, P7MS-25, P9XJ-25, P9AA-25, P9QA-25, Q7MS-25, Q8AF-30, Q8AX-30, Q8AF-30, Q8KX-30, P8AA-30, Q8TA-30, Q8KD-30, W8KD-30, P5KX-30, Q2AA-30, Q7AX-35, Q7AR-35, Q7JX-35, Q7JA-35, Q7VG-38, Q7AU-38,Q6EC-38, Q5EC-38, P5MR-38, Q3JX-43, W3XA-43, Q3XA-43, Q3XD-43, Q3HA-43, M8T,etc

Cutting teeth for betek equipment:

BG30P, BGF30, BGF26, B47GK, BGK86, BGK38, B47GK22, BG30K, BGK100, BGK96, BGS102, BG30W, BGS89, BGS100, BGS90, B47GK22, BHR35, B43G, BHR183, BSR271, BG32FL, BG32P, BSR262, BSR294, BHR205, BG32W, BSR247, BG33P, BG32P, BSR274, BHR224, BHR213, BHR243, BG35H, BSR228, BSR288, BR88, BG35K, BSR259, BSR175, BS38W, BKS154, BKS156, BKS172, BKS190, BHR38, B43H, BG38H, BSR292P, BR76, BR57, BG38K, BSR297, BSR189, BSR160, BSR125, BHR222, BHR219, BG38W, BSR199, BSR201, BSR200, B38H, BSR131, BSR215, BS43H, BSR236, BSR258, BSR265, BHR159, BR79, BF33, BF39, BF38, BF45, 55, B40K9, BG25K, BTK128, BTK129, DV25, BHR31, etc

Cutting teeth for kennametal equipment:

U85-30, U85HD, U85HDHF, U95, U95HF, U94, U94HD, U94HF, U170LR, C21, C21HD, C31HD, C31, C32, U40HD, U765HD, TS5, TS8, U47, S100, AM514, CJ2, U7, U7L, BSK157, AM514, S100, S120, S135, S170, FC-899, Hydra FC-947, Hydra FC-1007, U170, U135, U82, U84, U92, S150, S160, etc

We summarize the design experience in actual use, Coarse grain high cobalt-carbide tungsten carbide was selected, The cutter body is formed by warm extrusion, High-speed steel layers were coated on the pick′in the base by surfacing welding technology and bonded with the base metal Metallurgically. Therefore, it has the advantages of good wear resistance, high bending strength and high hardness under high impact temperature.

Type of Cutting teeth

- According to the type of alloy head can be divided into cap type and embedded.

- According to the tooth handle can be divided into standard tooth handle and stepped tooth handle

- According to the fixed way of the truncated teeth, it is divided into low-end clasp, built-in clasp and friction clasp

- In order to better protect the main body of the cutting teeth, alloy rings can be provided