We take special care in the manufacturing process to ensure that the cemented tungsten carbide in Rock mine’s tools will meet our customers’ demanding needs. The tungsten carbide is processed through a proprietary method to maximize its strengths and brazing properties. A special brazing/heat treatment bonds the tungsten carbide to high-grade alloy steel to ensure the hardness of the steel – and the superior performance of these tools in the field.

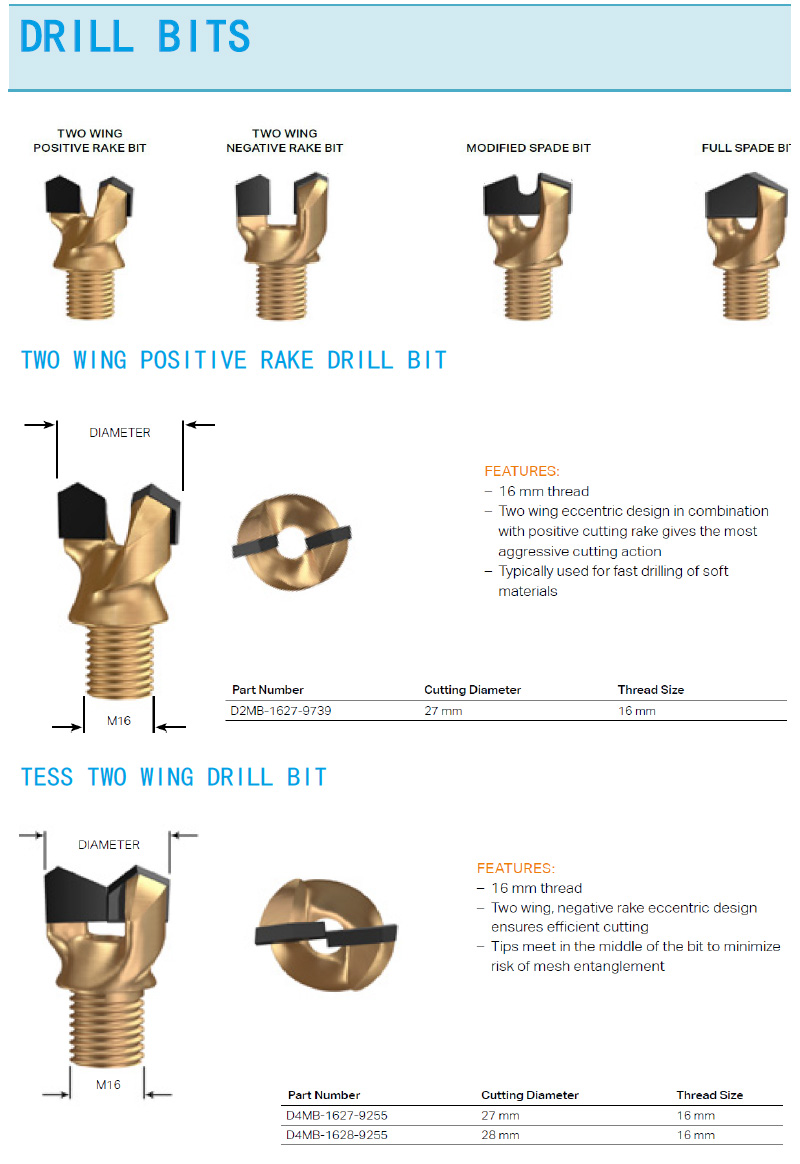

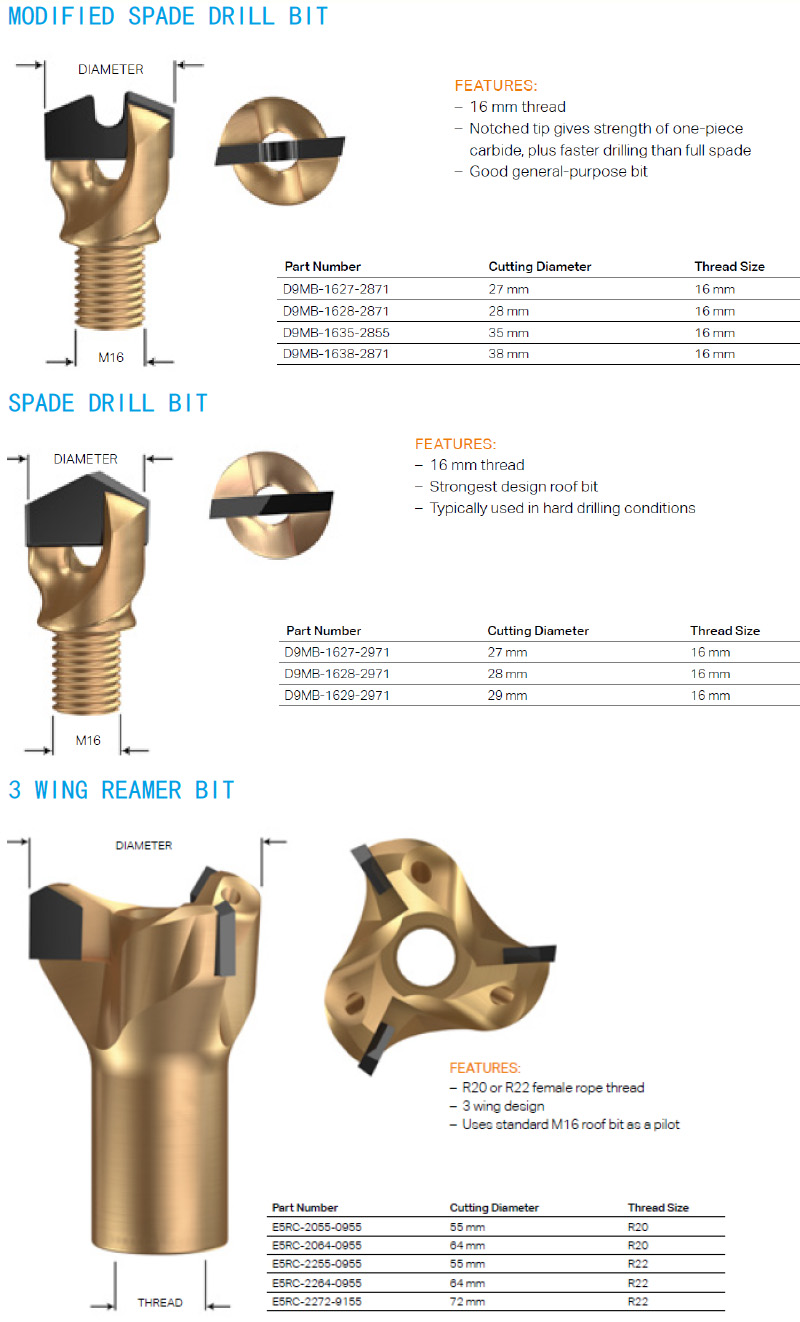

Our drill bits use unique carbide grades developed through years of experience and testing. We use the most appropriate grade in combination with concentric and eccentric geometries, along with positive and negative rake angles, to provide differing drilling capabilities for any application. Drill bit bodies utilise compound curve designs to maximise cutting efficiencies and cuttings removal.

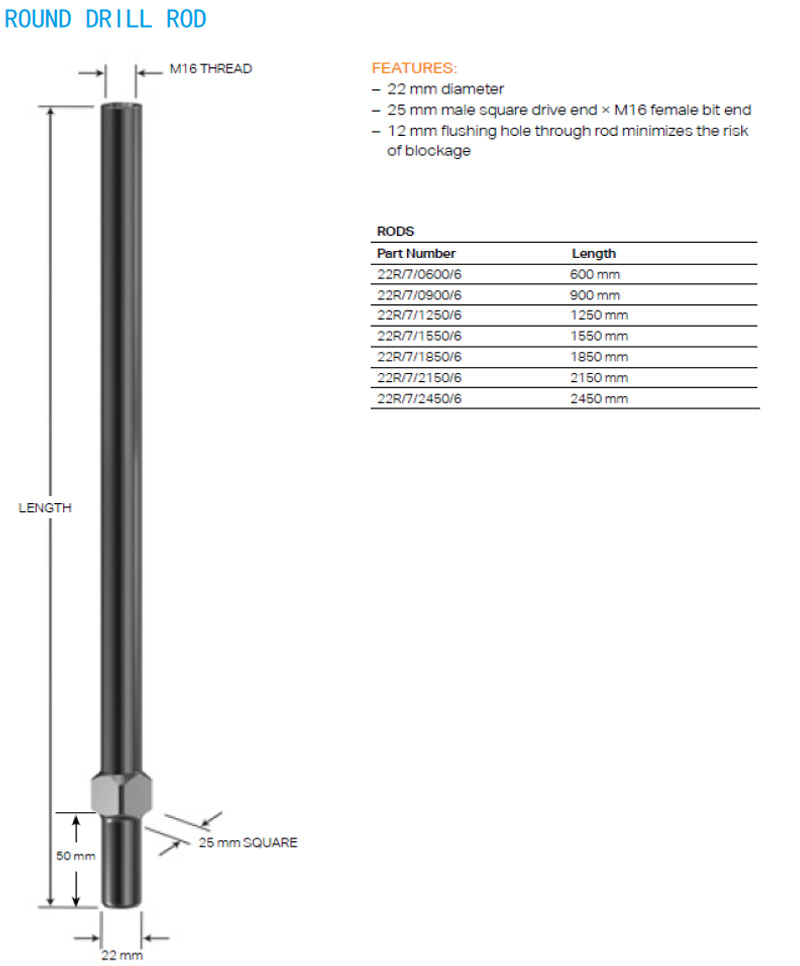

– Incorporating high-grade alloy steel

– Forged drive ends, for the best material flow and integrity

– CNC machining of threads, ensuring the highest tolerances

– Heat treatment, ensuring the highest strength

– Straightening and rust protection, processes ensuring the best quality product