Bottom line: Perfect the geometric structure, welding process, improve the overall quality of the drill.

Blast furnace iron bit, from the selection of structural materials, through the study of brazing technology, has formed a set of production technology, the test in the steel plant shows that the product performance meets the production requirements of blast furnace.Through product tracking analysis, defects are found in time, and continuous improvement is made in design and process to refine and perfect the production process of blast furnace drill, so as to achieve the optimal configuration of blast furnace drill bit, which not only improves the quality but also reduces the cost.

The alloy is characterized by high hardness, wear resistance, abrasion resistance, high temperature resistance and low linear expansion coefficient.Brazing solder has good wettability, can fully fill the gap of brazing joint, has a high melting point, at about 1000 ℃ does not melt.Ensure that a strong bond is formed between the filler and brazing metal.The solder has stable and uniform composition, does not separate due to liquefaction, does not contain strong volatile and volatile toxic elements, to meet the environmental monitoring standards.

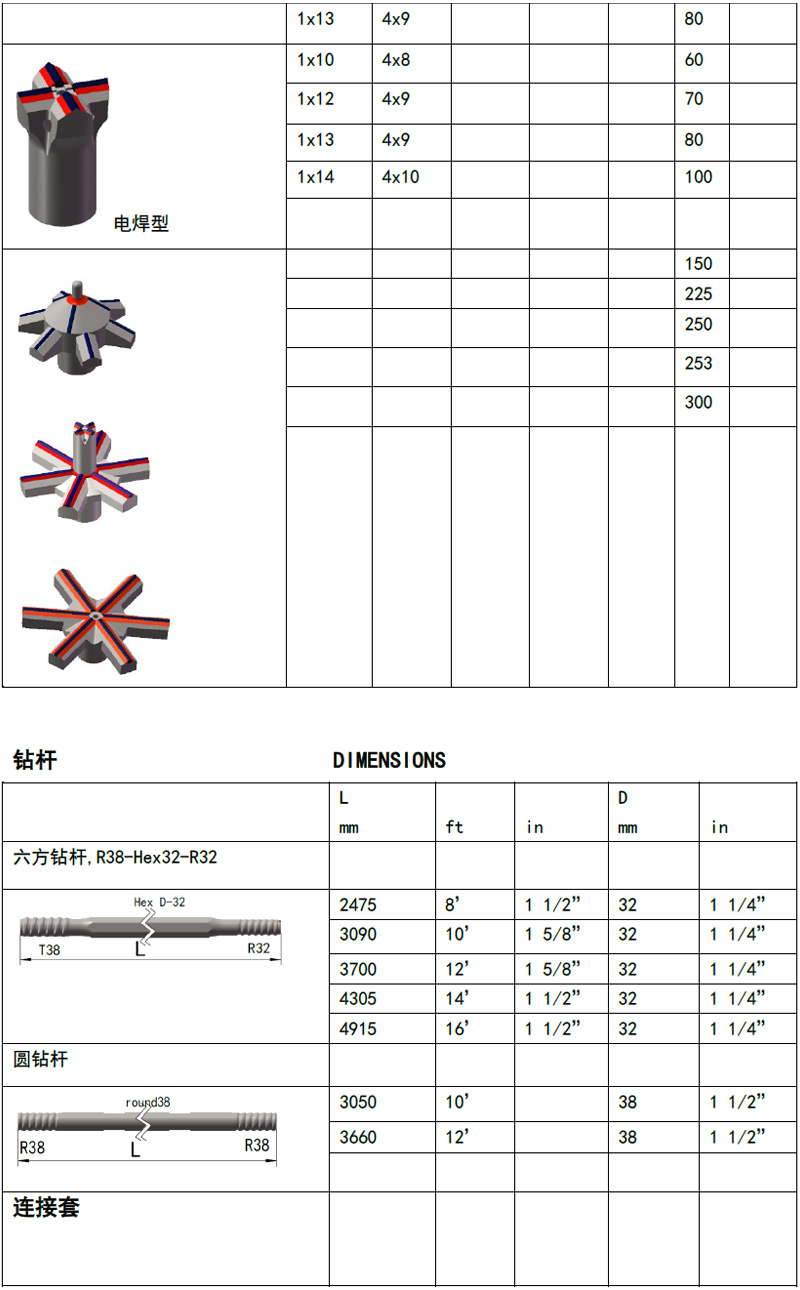

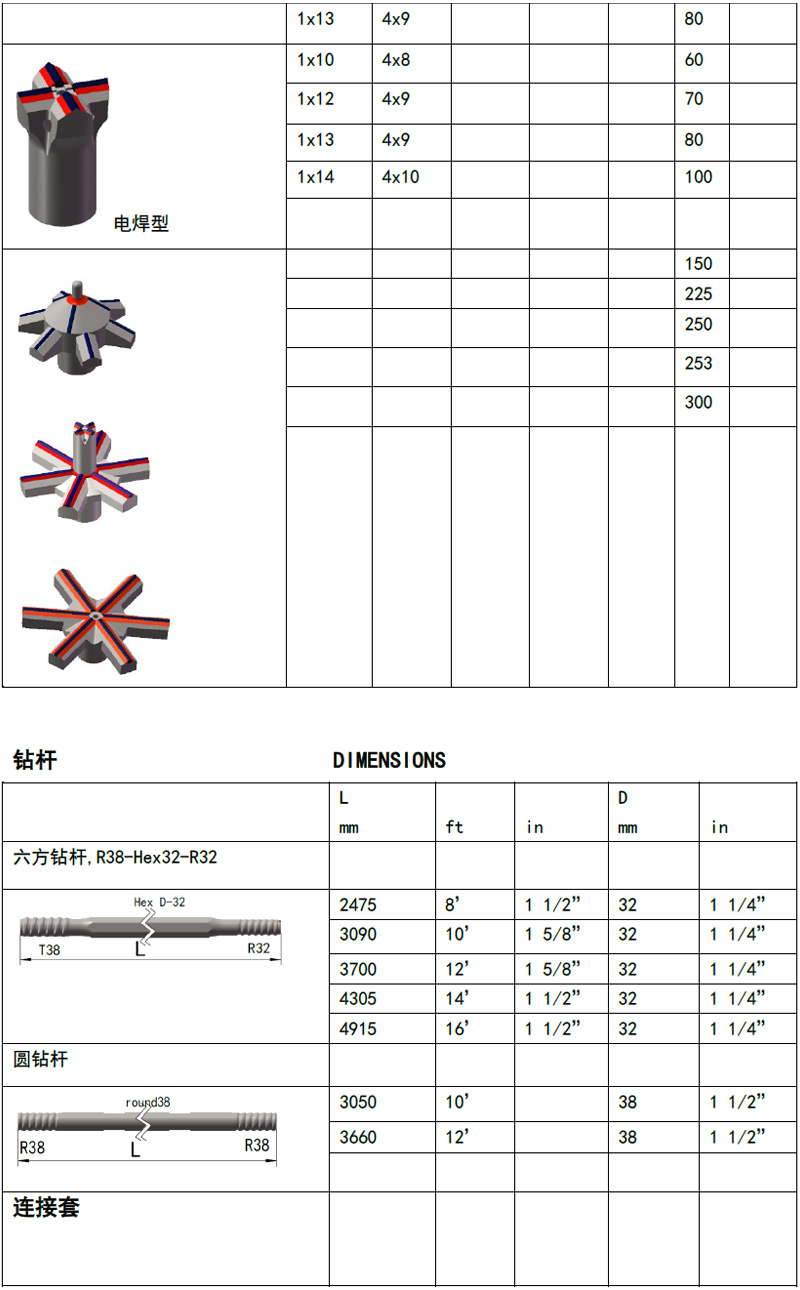

Type:

1) according to the connection mode of drill bit and drill pipe, there are taper connection and thread connection (R32,R38,T38,LR30,LR35, etc.).

2) according to the external shape of the drill, there are: Y140,Y142,Y145,Y155, etc.

Triairfoil : y45-R32, y50-R38, y55-R38, y60-R38, y65-T38, y75-T38, etc

Cruciform : s445-R32, s455-R32, s465-R38, s480-T38, s4100-T38, s4120-T38, etc

Ball tooth type : Q542-R32, Q650-R32, Q760-R32, Q1180-R32, Q655-R38, Q765-T38, etc

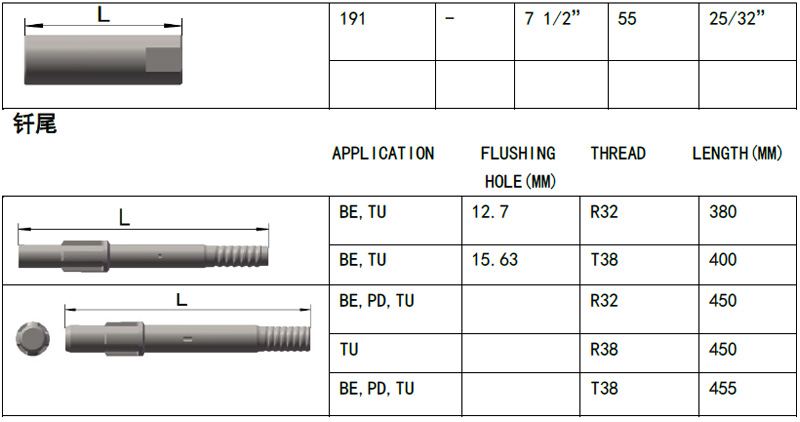

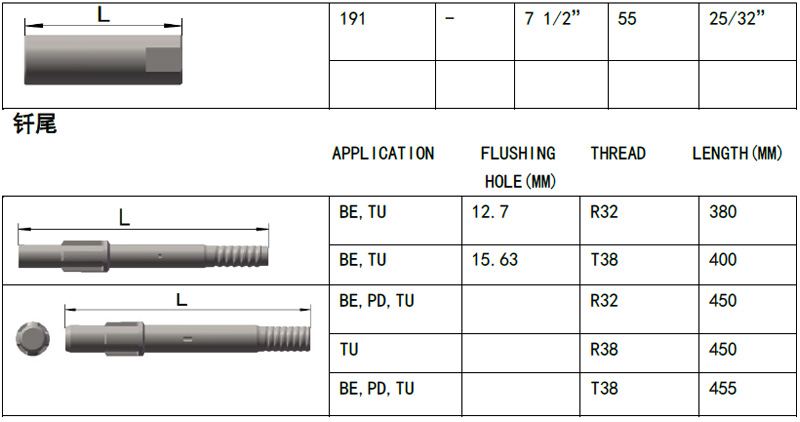

3) the drill pipe is hexagonal and round in shape:

R32 - D32-2475, R32 - D32-3700, R38 - D38-4305, R38 - D38-6300, T38 - D38-4305, R38 / R32 - D38-3700, R38-2475 - H32 - R32, R38-3700 - H32 - R32, T38-2475 - H32 - R32, etc

4)SHANK ADAPTERS: BE,PD,TU.R32-380,R32-450,R38-450,T38-400,T38-455,etc

The alloy is characterized by high hardness, wear resistance, abrasion resistance, high temperature resistance and low linear expansion coefficient.Brazing solder has good wettability, can fully fill the gap of brazing joint, has a high melting point, at about 1000 ℃ does not melt.Ensure that a strong bond is formed between the filler and brazing metal.The solder has stable and uniform composition, does not separate due to liquefaction, does not contain strong volatile and volatile toxic elements, to meet the environmental monitoring standards.