Type:

Cold regeneration knife head, Tool head of road milling machine, Toolholder-Base of road milling machine, Toolholder, Base, Bushing, etc

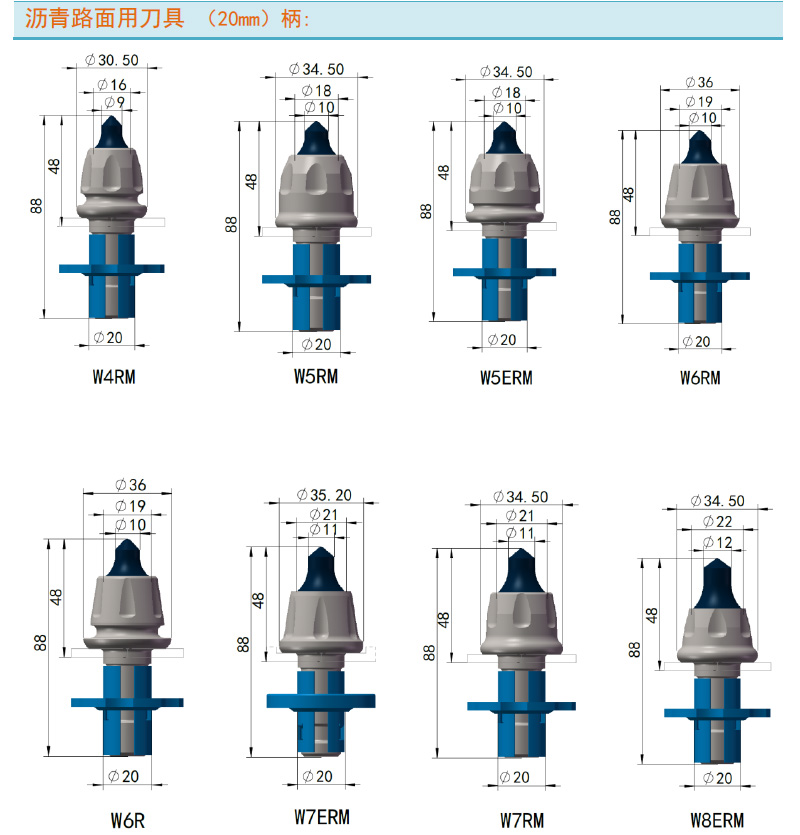

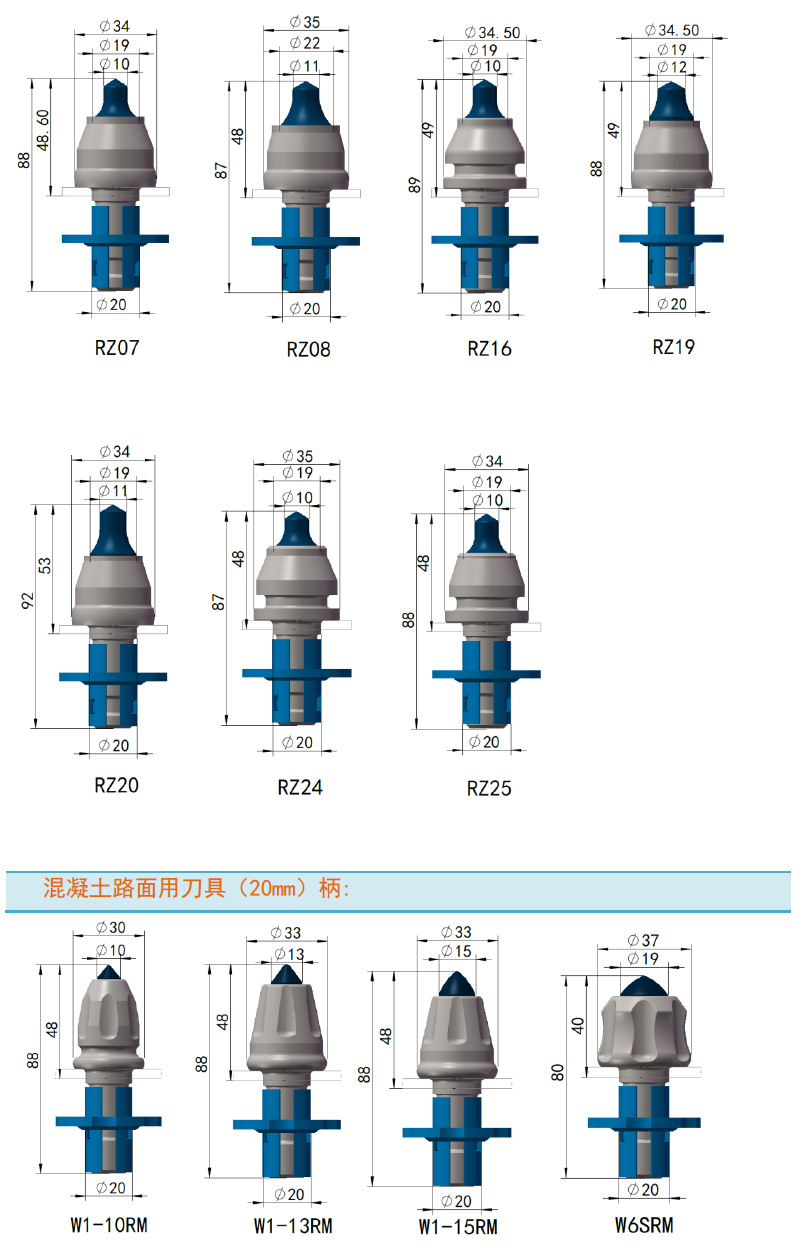

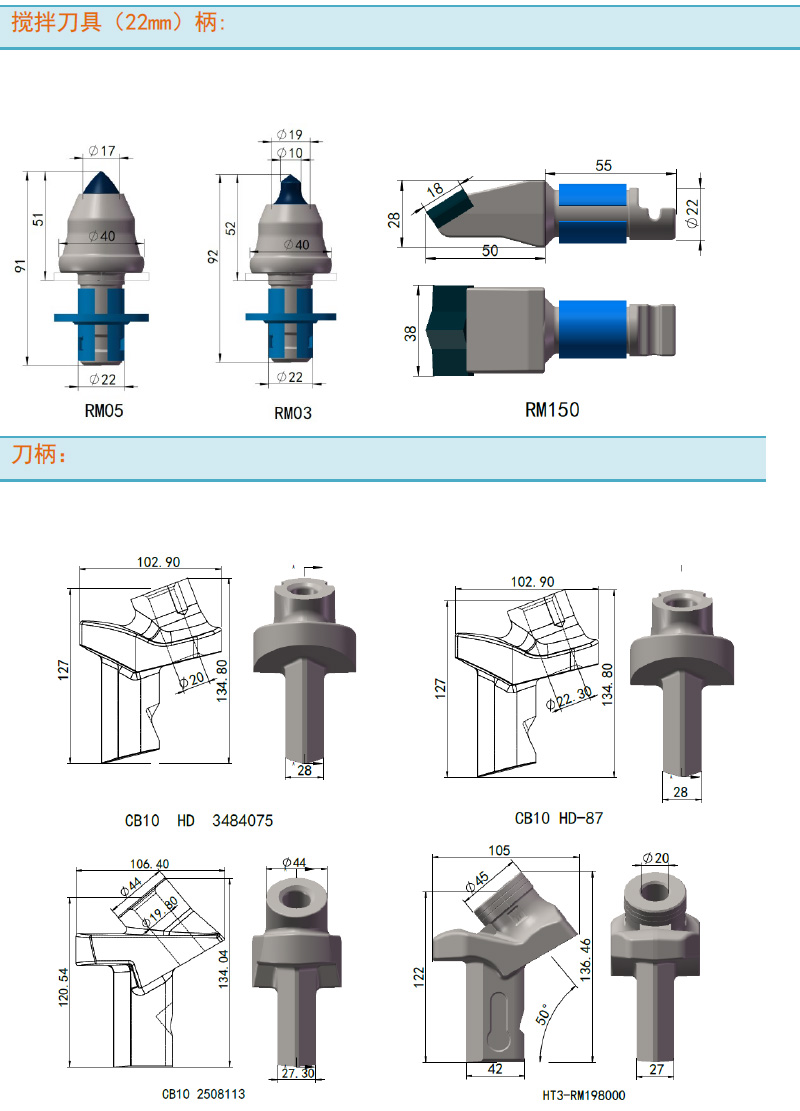

Teeth for wirtgen milling machine:

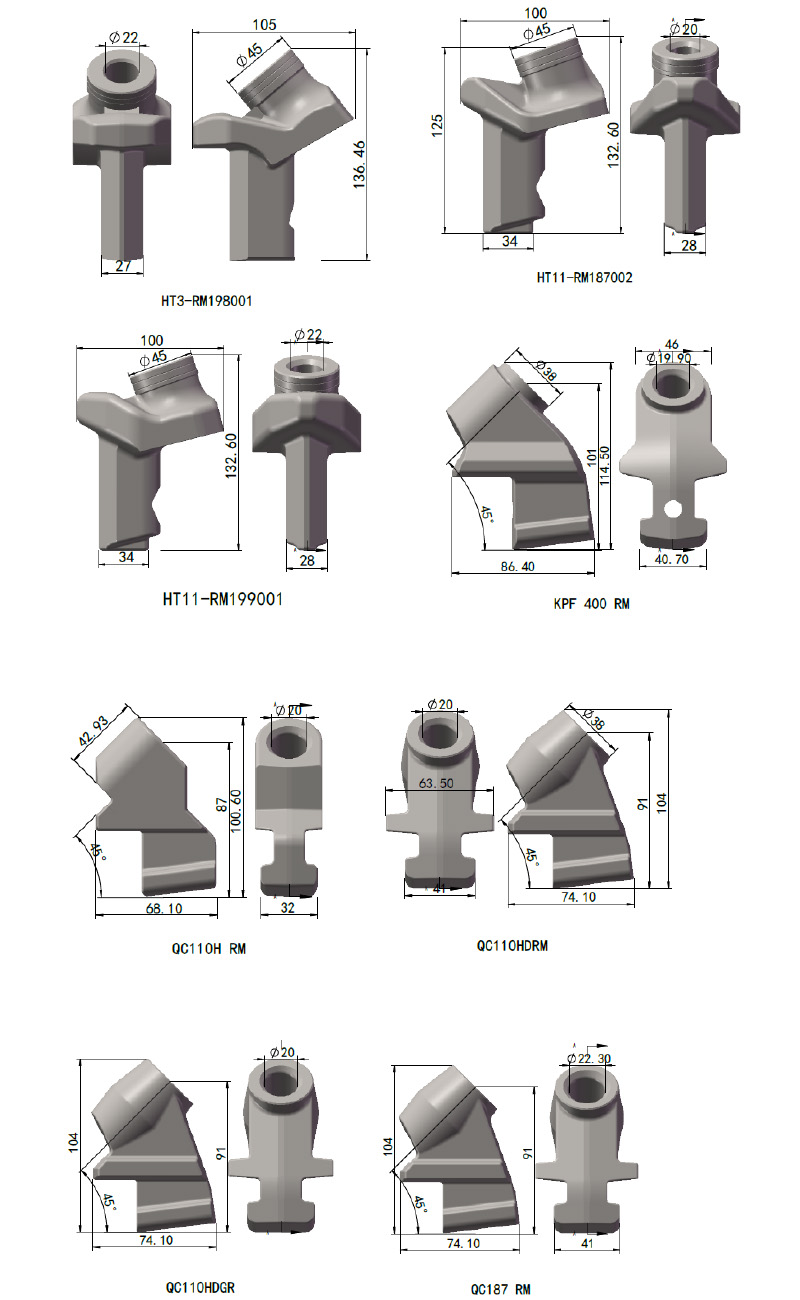

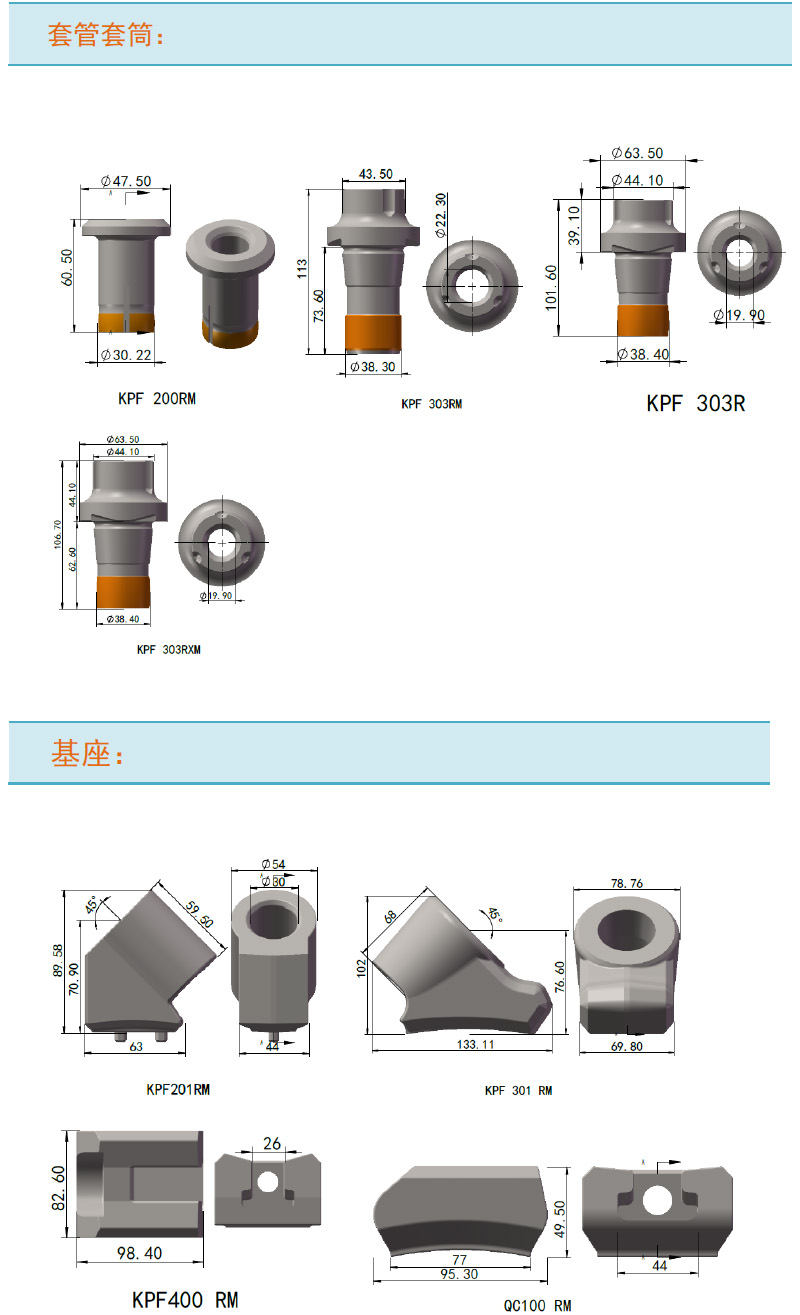

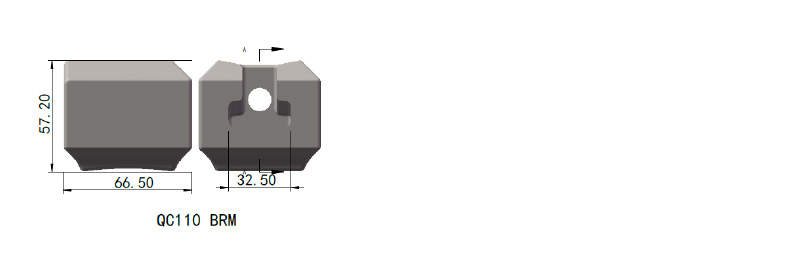

W1-13/22, W1-17/22, W6SR, W4ER, W5ER, W5EHR, W6R, W6HR, W6ER, W6EHR, W6SR, W6SGR, W7ER, W7EHR, W7EHLL, W8EHR, W1-10R, W1-13R, W1-15R, CB10HD, CB10HD-87, CB10, QC110H, QC110HD, QC110HDG, QC187, QC11087, HT3, HT11, KPF201, KPF301, KPF400, QC100, QC110 , etc

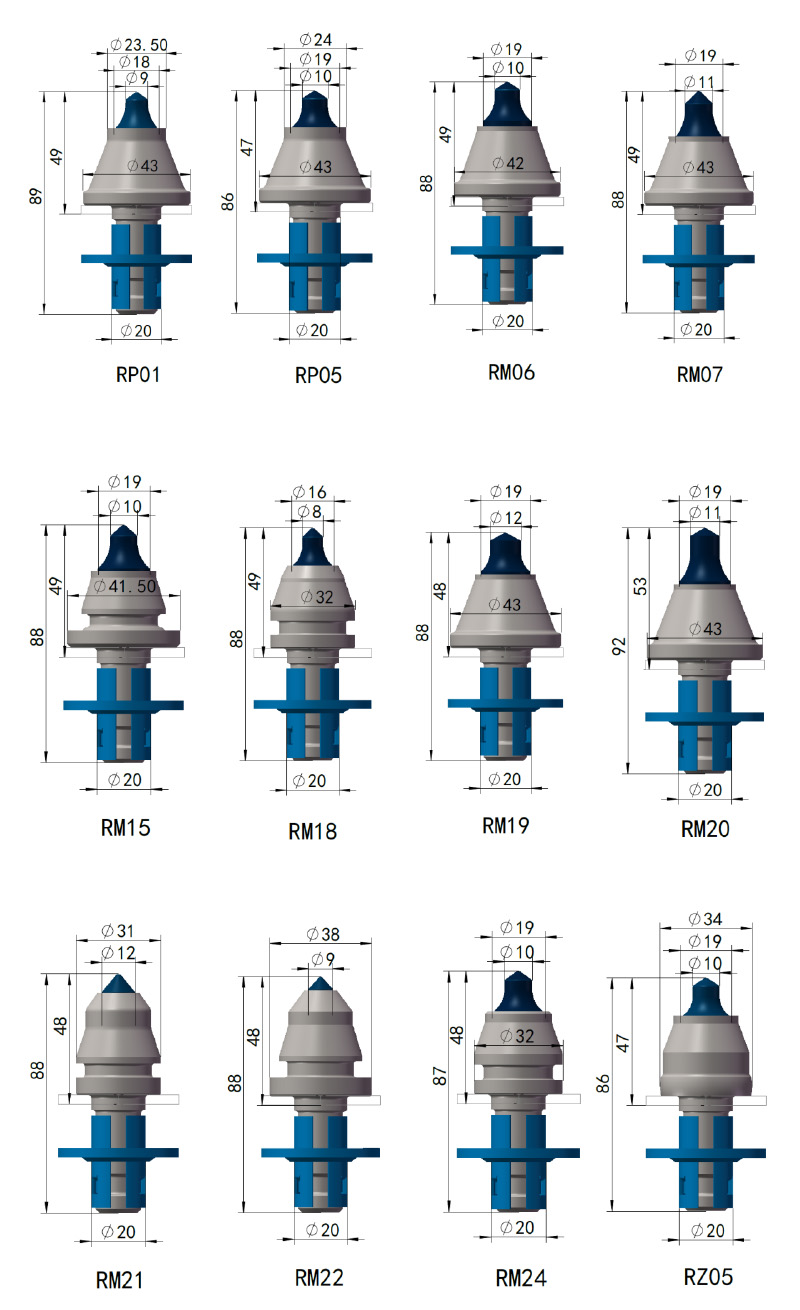

Teeth for Kennan matt (Kennametal’s) milling machine :

RZ05, RZ07, RZ08, RZ19, RZ20, RZ16, RZ24, RZ25, RP01, RP05, RP06, RP07, RP19, RP20, RP26, RP10, RP11, RP15, RP16, RP30, RP18, RP24, RP25, RP27, RP28, RP21, RP22, RPM18, C3KBF, RS12, RS19, RS14, RS16, RS18, SR01, SR02, SR03, SR04, SM01, SM02, SM06, SM03, SM04, SM07, CM41, CM42, CM61, CM63, KPF200R, KPF303-87, KPF303R, KPF303RX, etc

We delivers productivity to customers seeking peak performance in demanding environments by providing innovative custom and standard wear-resistant solutions, enabled through our advanced materials sciences, application knowledge, and commitment to a sustainable environment.

- Features replaceable, rotating, self-sharpening, solid carbide-tipped cutting tools that wear uniformly and last longer

- Reduces machine and operator downtime significantly by eliminating the need to replace entire blade sections and instead, allowing for the quick change of individual tools.

- Lower operating costs,Reduced fuel consumption,Increased uptime and performance!

Application environment and model: