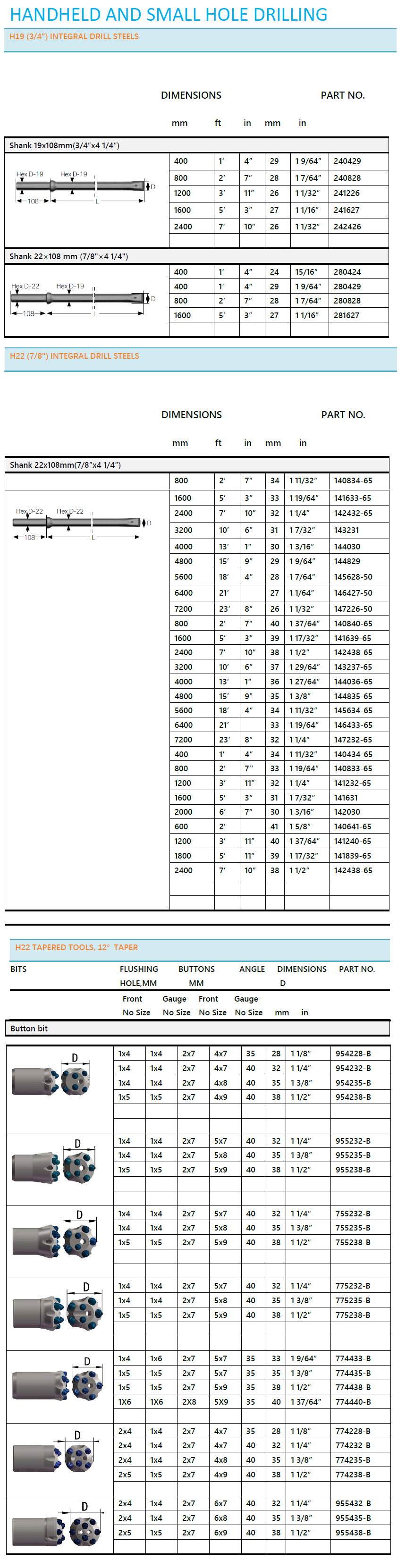

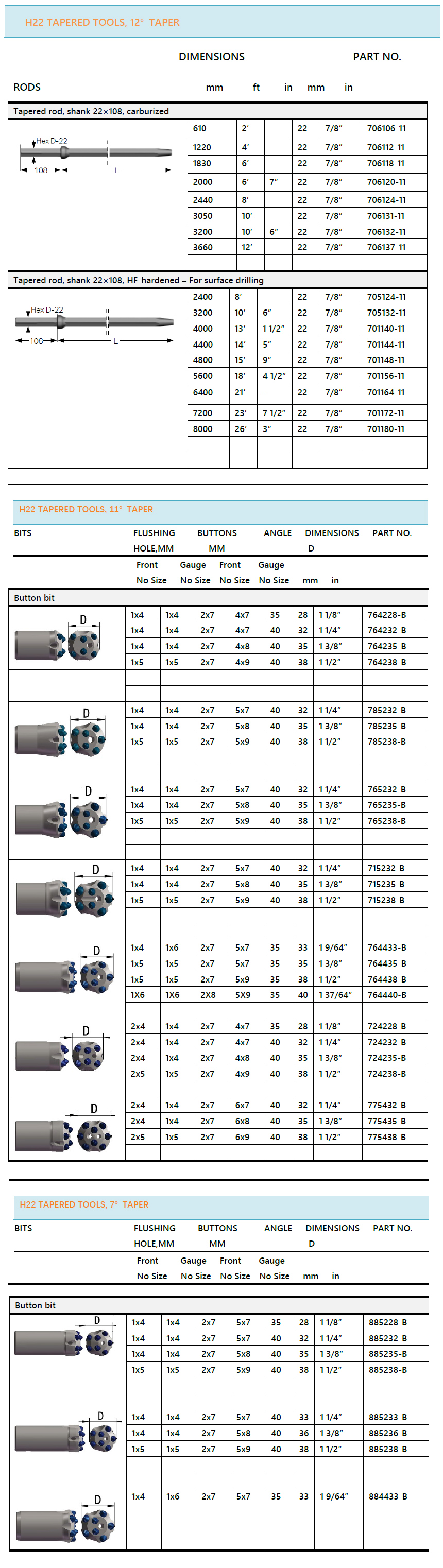

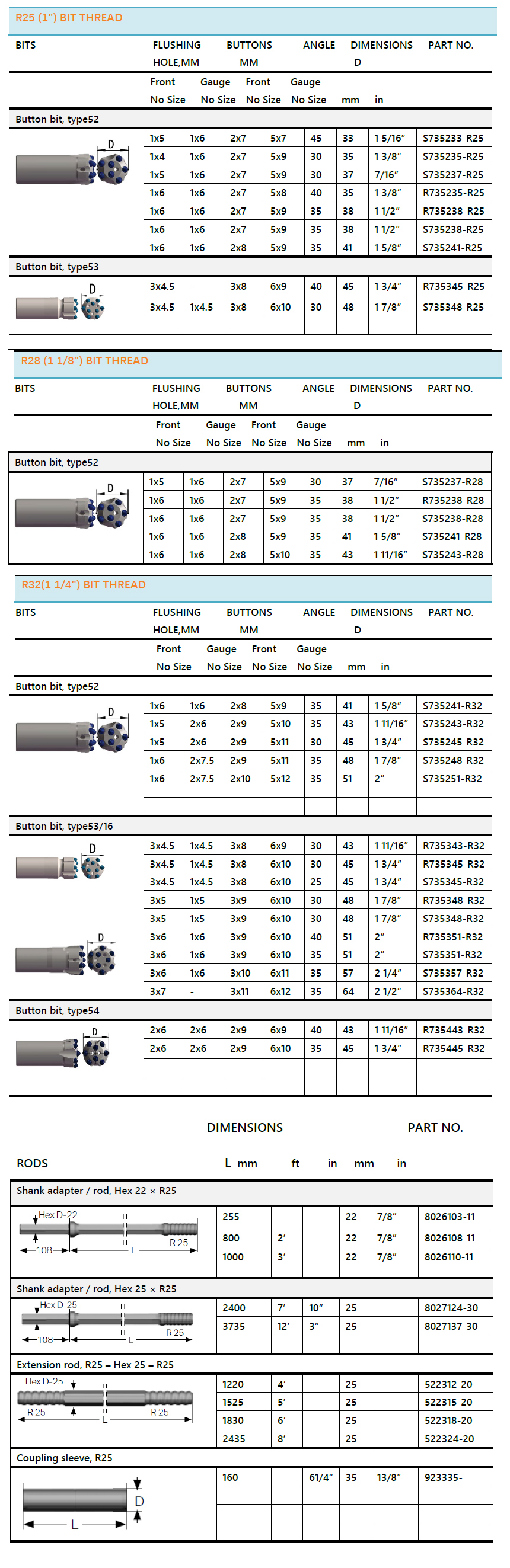

Drill pipe type:

H19, H22, R22, R23, R25, 11°, 12°, 7°, 108, etc

Bit type:

Button bit, Button bit, integral dral steels, A cross-type drill bit hoofs, horseshoe shaped drill, box-thread bit, Coupling sleeve, etc

Type:

y128, y130, y132, y136, y138, y140, y142, y143, y145, s38, s40, s42, s45, Q440, Q542, Q645, Q745, Q745-R22, Q745-R25, Extension rod R22 – Hex 22 – R22, Shank adapter/Shank rod, Hex 22 – R22, R22, etc

Drill bits have cemented carbide buttons. Cemented carbide is made up of tungsten carbide and cobalt. Grinding buttons can produce dust and fumes containing dangerous substances that can be inhaled or swallowed, or which can come in contact with the skin or eyes. Do not breathe the dust. Wear protective gloves, protective clothing and eye protection. In case of inadequate venti-lation,wear respiratory protection. In particular, avoid dry grinding

ASSEMBLY OF BITS

– Do not touch any equipment while it is rotating.

– Rod rotation must be stopped before the installation or removal of a drill bit.

– Follow site instructions for the isolation of rotation motors.

– Beware of pinch points between the bit and the rod.