Series:

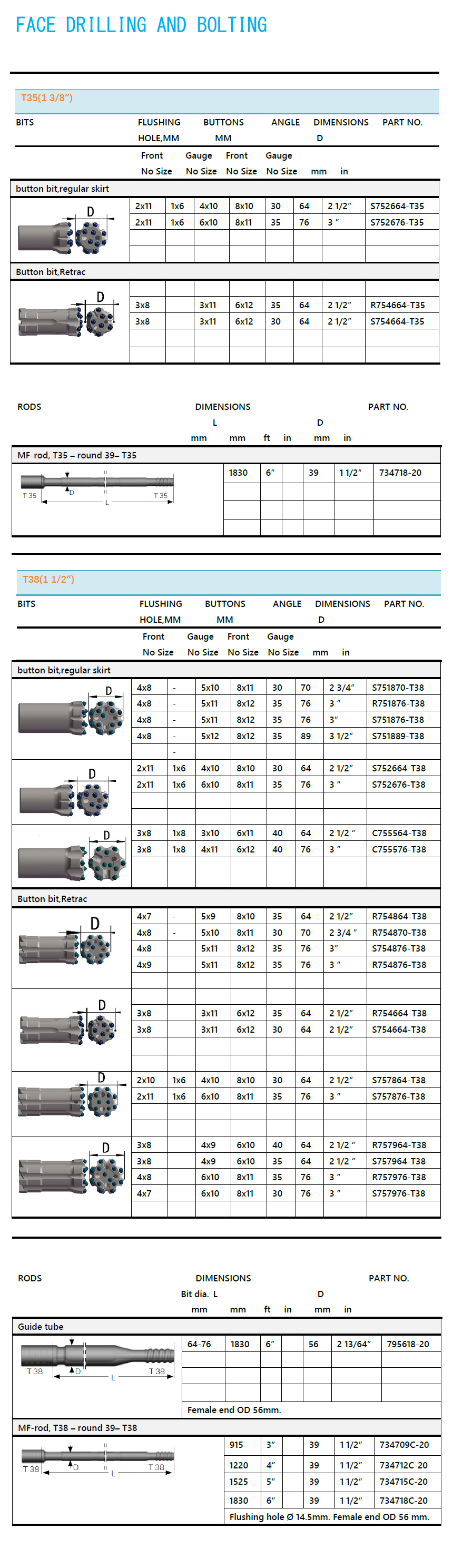

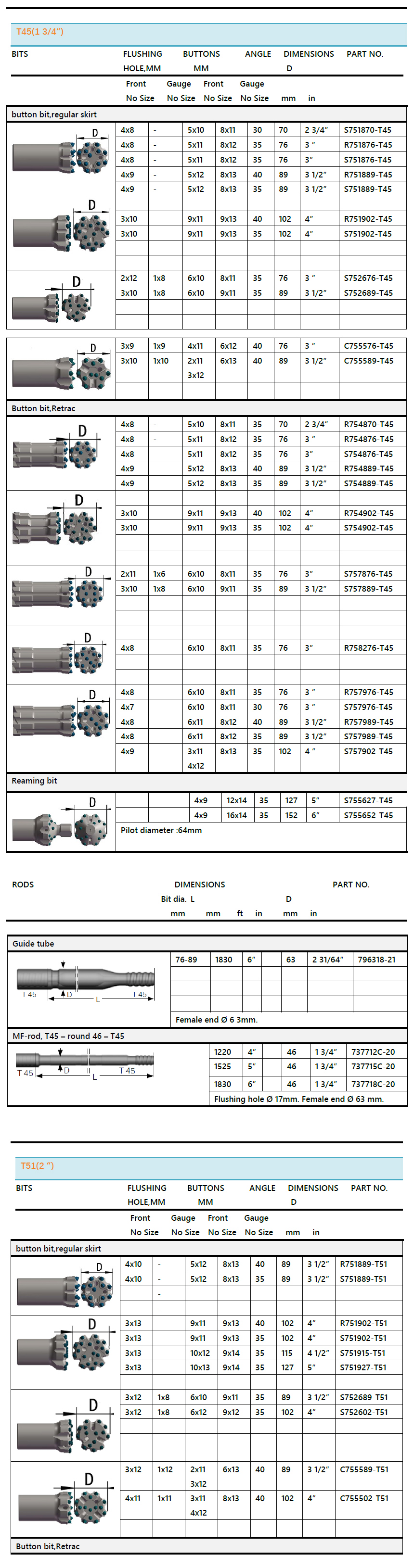

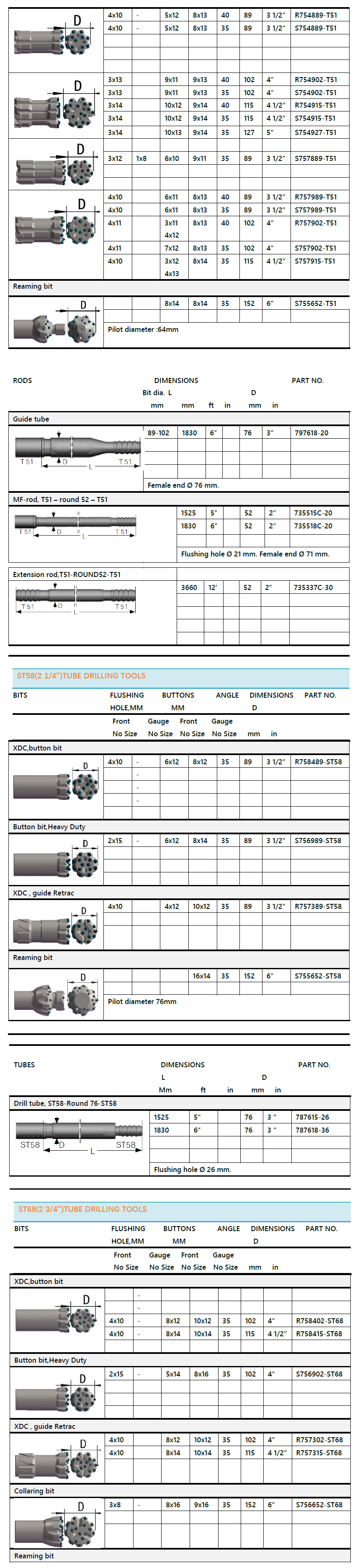

Cross bit, Button bit, Reaming bit, Button bit, Retrac, Button bit, regular skirt,

Thread form:

R32, R35, R38, T45, T51, GT60, ST58, ST68, HL, S48, R48, α330, M32, M45, M51, etc

Type:

Q945-R32, Q948-R32, Q751-R32, Q964-R32, Q1376-32, Q964-R38, Q1276-R38, Q1389-T45, Q11102-T45, Q11102-T51, Q19115-T51, Q19127-T51, Q18115-GT60, Q19115-ST58, Q19127-ST68, etc

Drill:

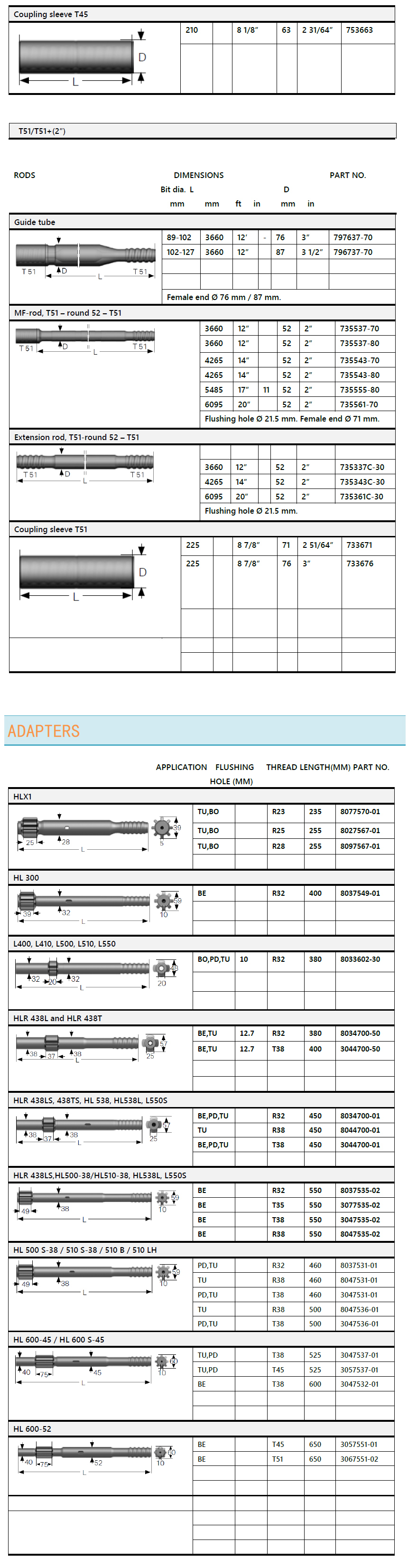

Guide tube, MF-rod , MF-rod, T51 – round 52 – T51, Extension rod, T51 – round 52 – T51, Coupling sleeve T51, MF-rod, GT60 – round 60 – GT60, Drill tube, Pilot tube, Pilot adapter for reaming, Reaming bit, etc

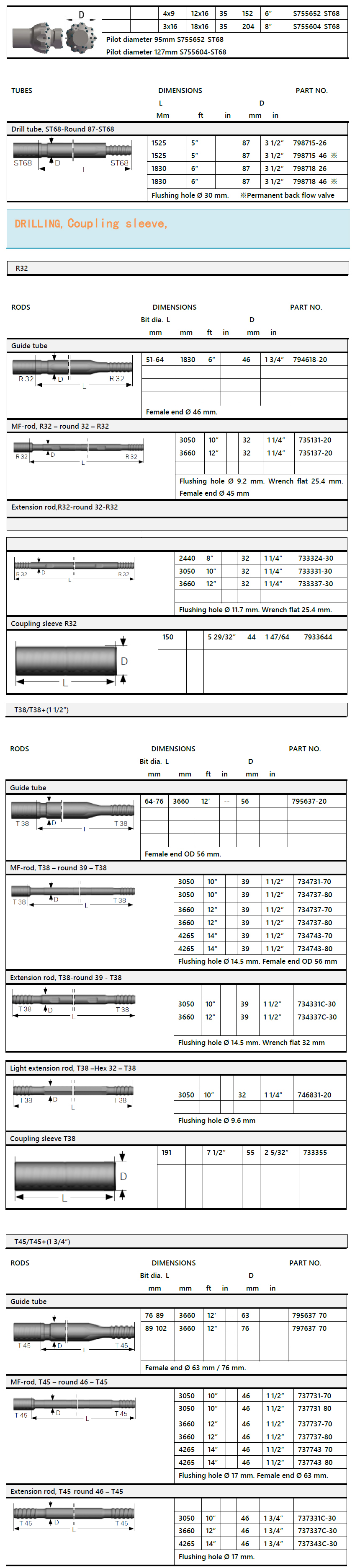

ADVANTAGES

–– Our top center design extends grinding intervals by up to 80 percent* compared to our previous design, reducing your bit cost per drilled meter.

–– Extended bit life by up to 60 percent* compared to ourprevious design means fewer bit changes and thusmore drilling productivity.

–– Longer tool life means operators don’t need to leave the safety of the drill cabin as often to change bits in potentially hazardous areas, such as unreinforced faces.

–– Larger flushing holes increase flushing volume by up to 30 percent while maintaining strong penetration rates.

–– More accurate collaring improves accuracy of drilled holes and consequently blasting results.